Finolex Casing Pipes

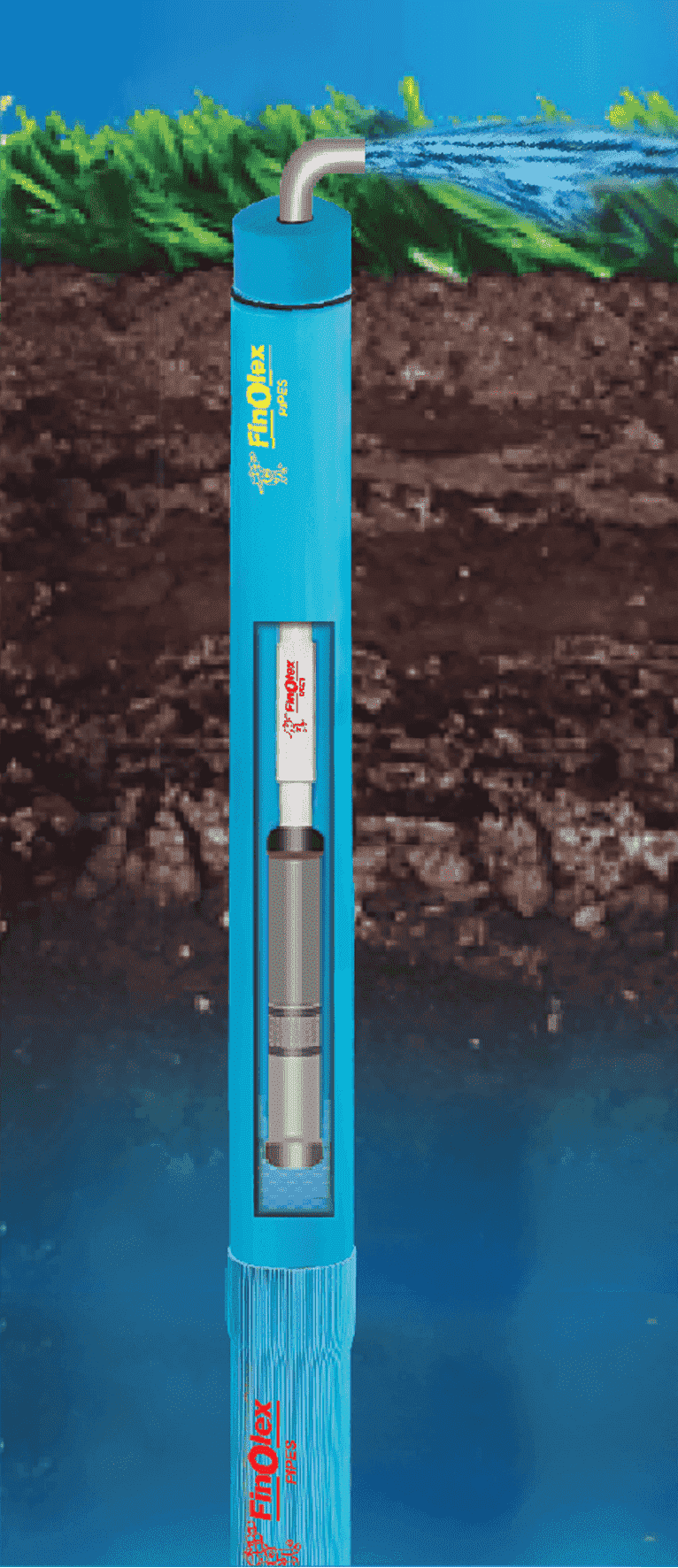

Finolex casing and ribbed screen pipes are manufactured using a special Lead Free PVC-U compound which makes them ideal for the transportation of hard, salty, sandy or chemically aggressive water. Finolex range of PVC-U plain casing and ribbed screen pipes are specially designed to protect water lines from soil conditions.

This special design makes them ideal for domestic wells, industrial wells, public and mining wells. These pipes are also anti-corrosive, which prevents chemicals in the soil from affecting them.

Finolex casing and ribbed screen pipes are better than conventional metal pipes as they are lightweight, corrosion free and long lasting. These pipes do not alter the water quality and are recyclable. Casing pipes are easy to install as the threaded ends ensure that the pipes can be interlocked without the use of cements or adhesives.

Our stringent quality assurance approach across all stages of manufacturing gives the product a high degree of reliability making Finolex casing pipes a preferred choice for farmers, users in domestic and commercial establishments, and quality conscious people across the country.

Our wide range of casing and ribbed screen pipes, CS (Shallow well casing), CM (Medium well casing)

CD (Deep well casing) and Ribbed Screen (RMS & RDS) Pipes. These pipes are available in 40 mm (1.1/2”) to 250 mm (10”) sizes for different well depths. Our varied range of casing pipes conforms to the IS 12818 and ASTM D 1785 standards, and caters to diverse bore well requirements.

Casing Pipe Applications

Technical Details

Following factors may result in pipe deformation and bursting. Bore mechanics should take care while installation:

• Hydraulic pressure difference created by inside water and outside while drilling mud.

• Hydraulic pressure and heat created during bentonite/cement grouting.

• Stress formation due to types of rocks, clay and shale present outside the pipe.

• Development of sudden internal vacuum inside the pipe.

• Lateral compression and brittle failure after external impact of the hard bedrock.

Additional information

CASING PIPE INSTALLATION GUIDELINES

|

• Drill the bore of the required size and depth in the ground. Care should be taken that it is vertical, without any bends. |

|

CERTIFICATIONS AND APPROVALS

• Casing and Ribbed Screen pipes are manufactured conforming to IS 12818 (Bureau of Indian Standards) and as per ASTM D 1785.

• Approved and tested by CIPET (Central Institute of Plastics Engineering & Technology).

FAQ

-

What are the various types of Finolex casing pipes and where is it used?

Finolex offers casing pipes in - CS (Shallow Casing- for well depth of 80- meters), CM (Medium Casing- for well depth from 80 to 250 meters), CD ( Deep Casing -- for well depth between 250-450 meters). All in plain and slotted types; Ribbed Screen, with slottings, Casing pipes in SDR series (for well depth from 12 to 24 meters )-Plain & slotted, ASTM Dark Blue casing pipes in SCH 40, SCH 80.These are available in various sizes. For more information refer to the Finolex Casing Pipes Brochure.

-

How is slotting on Finolex pipes different?

In Finolex pipes, slotting is done perpendicular to the axis of the pipe i.e., horizontal slotting is done with the help of state-of-the-art CNC machines, without compromising the strength of the casing pipes. This is as compared to the products available in the market where slotting is done vertically, along the length of the pipe, which reduces the strength of the pipe.

-

In CS, CM, CD type of casing pipes, how jointing is done?

These Casing pipes are easy to install as the threaded ends make sure that the pipes can be interlocked without the use of solvent cement. There is perfect interlocking of male threading end of one pipe and the female threading end of the other pipe.

-

Are PVC casing pipes better than conventional metal pipes?

Finolex casing pipes are lightweight, easy to transport and install and do not corrode. They are more economical, and last for years. It does not impart any taste, odour or colour and it does not release any harmful substances into the water hence safe for potable/drinking water. All these qualities and features make them better than conventional pipes.

-

Where casing pipes are recommended?

Casing Pipes are used in borewells, especially where soil is highly collapsible, after drilling like sandy-loose soil and silt. The casing pipes protect the bore from collapsing.