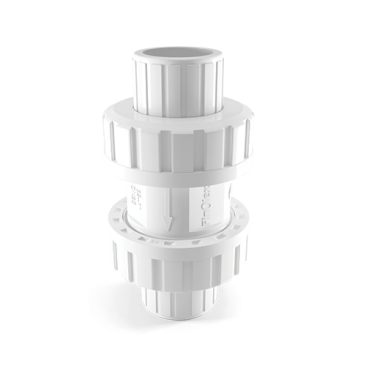

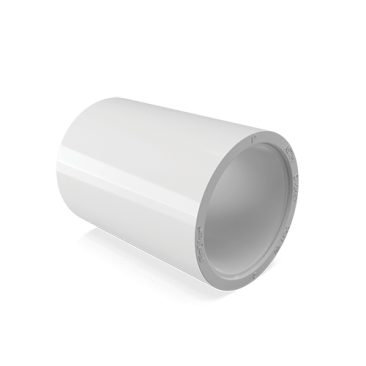

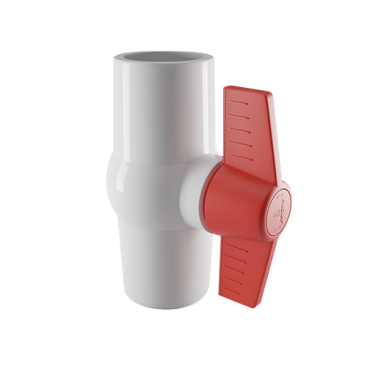

ASTM Pipes & Fittings

Finolex ASTM Pipes are manufactured using the latest technology and high-grade raw material.

These pipes are ideal for transportation and distribution of water in households including potable water, industrial process lines, saltwater lines, swimming pools, pipes used for hand pumps, and in down-take lines in plumbing systems.

Manufactured with added strength and crafting precision, Finolex PVC-U pipes have a prolonged life advantage over conventional pipes surpassing most or all traditional metal and other plastic pipes.

This lightweight product’s abrasion resistance, mechanical strength, toughness, and durability are the key reasons why we are a leader in housing and potable water applications in the plumbing industry.

These pipes are manufactured using a lead-free compound and are environment and health friendly.

Our stringent quality assurance approach across all stages of manufacturing gives this product a high degree of reliability, making Finolex ASTM plumbing pipes a preferred choice of leading MEP consultants, architects, builders, plumbing contractors, plumbers, and quality conscious people across the country.

Manufactured in accordance with ASTM D 1785 standards, these pipes are available in Schedule 40 & 80 series, in standard lengths of 3 and 6 meters, with options of plain or threaded ends.

Application

Finolex ASTM plumbing pipes are designed for potable water distribution as well as plumbing applications. Note: Not suitable for compressed air and gases.

Technical Details

PIPE DERATING FACTOR

PVC-U ASTM Plumbing pipes can be used at higher pressure ratings for a water temperature of 23°C. As the

temperature of water increases, the working pressure reduces (e.g. if the working pressure is 100% at 23°C, it will be 50% at 45°C and only 22% at 60°C). These pipes may be used for water temperatures up to 45°C. However, occasional rise in temperature does not have any adverse effect on the life of the product.

| Service Temperature (°C) | 23 | 30 | 35 | 40 | 45 | 50 | 55 | 60 |

| % of working pressure | 100 | 90 | 75 | 62 | 50 | 40 | 30 | 22 |

THERMAL EXPANSION

Thermal expansion of PVC is roughly 4.5 to 5 times more than metallic pipes. As long as PVC-U ASTM plumbing pipes are buried & are used for conveying cold water, thermal changes do not have any adverse effect on the durability. But in case of exposed lines & for high fluid temperatures, thermal expansion & contractions need to be considered.

The change in the length of a pipeline can be calculated as :

δl = α × L δt

Where δl : Change in length in mm

α : Coefficient of linear expansion of PVC

L : Length of pipe in mm (at Ambient Temperature)

δt : Difference between ambient temperature & maximum operating temperature.

JOINTING

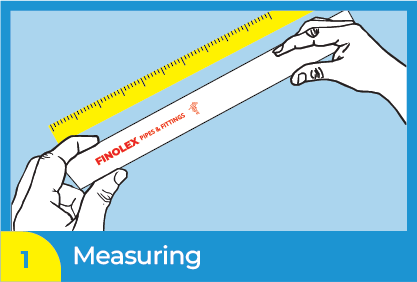

|

1. Measuring : Measure the required length of pipe and marking done. |

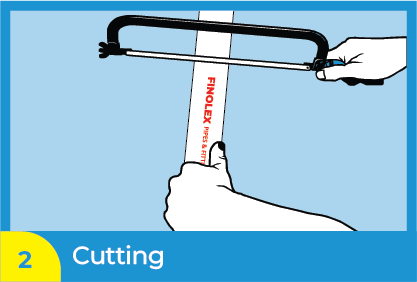

|

2. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

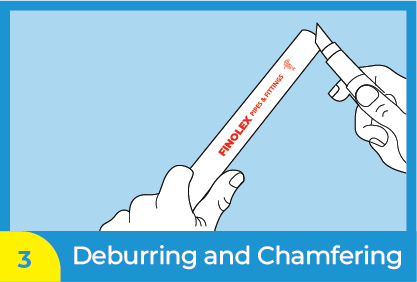

|

3. Deburring & Chamfering : All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe. |

|

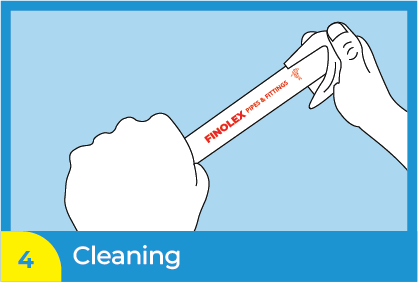

4. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

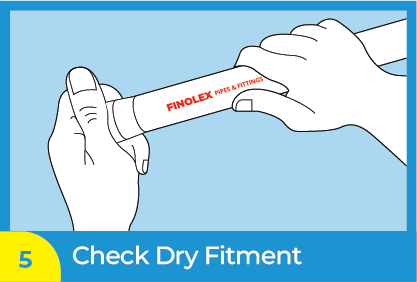

5. Check Dry Fit : Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used. |

|

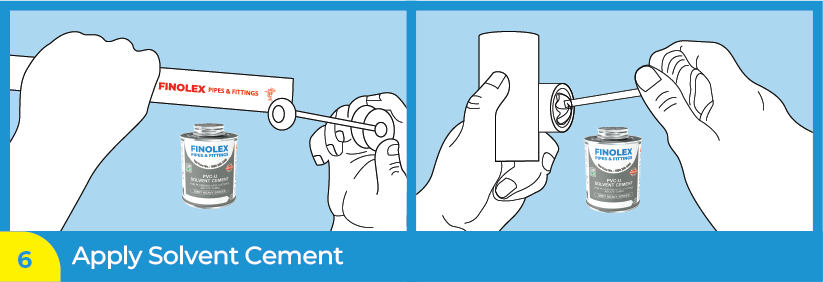

|

6. Solvent Cement Application : An even layer of cement should be applied to the outer side of the pipe and a medium layer of the plumbing solvent cement to the inside of a fitting. |

|

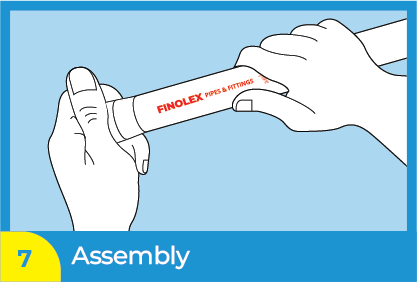

7. Assembly : Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting. |

SET & CURE SCHEDULE GUIDELINES

AVERAGE INITIAL SET SCHEDULE

Set schedule is the necessary time to be allowed before the joint can be carefully handled.

(In damp or humid weather allow 50% more set time.)

| Temperature Range | Pipe Sizes | Pipe Sizes | Pipe Sizes |

| Temperature range during assembly and setting period |

½” to 1¼” | 1½” to 2” | 2½” to 8” |

| 16°C to 38°C | 2 minutes | 5 minutes | 30 minutes |

| 5°C to 16°C | 5 minutes | 10 minutes | 2 hours |

| -18°C to 5°C | 10 minutes | 15 minutes | 12 hours |

AVERAGE JOINT CURE SCHEDULE

Joint Cure Schedule is the necessary time to be allowed before pressurizing the system.

(In damp or humid weather allow 50% more set time.)

| Temperature Range | Pipe Sizes | Pipe Sizes | Pipe Sizes | |||

| Temperature range during assembly and setting period |

½” to 1¼” | 1½” to 2” | 2½” to 8” | |||

| Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

|

| 16°C to 38°C | 15 minutes | 6 hours | 30 minutes | 12 hours | 1½ hours | 24 hours |

| 5°C to 16°C | 20 minutes | 12 hours | 45 minutes | 24 hours | 4 hours | 48 hours |

| -18°C to 5°C | 30 minutes | 48 hours | 1 hour | 96 hours | 72 hours | 8 days |

FINOLEX SOLVENT CEMENTS & PRIMER

FOR ASTM PIPES & FITTINGS

1) Medium Duty PVC-U Solvent Cement

Medium Duty PVC-U Solvent Cement for plumbing applications up to 50 mm (2”)

(Meets ASTM D 2564 standard)

| ml | 118 | 237 | 473 |

| Container | Tin | Tin | Tin |

2) Heavy Duty PVC-U Solvent Cement

Heavy Duty PVC-U Solvent Cement for plumbing applications above 50 mm (2”)

(Meets ASTM D 2564 standard)

| ml | 118 | 237 | 473 |

| Container | Tin | Tin | Tin |

3) Primer for PVC-U plumbing applications (Meets ASTM F 656)

| ml | 237 |

| Container | Tin |

Additional information

DO'S

• Use pipes, fittings and solvent cements manufactured by Finolex Industries for best results.

• Installation should be completed as per instructions and recommended safe practices must be followed.

• Clean the pipe and fittings with a clean dry cloth to remove any dirt.

• Keep pipe and fittings in the original packaging until needed.

• In case any crack is found in the pipe, cut a minimum of 25mm length beyond the edge of the crack.

• Cut the pipe as square or perpendicular as possible before making a joint.

• Ensure no sharp edges are in contact with the fittings surface while inserting the pipe.

• Ensure proper alignment of pipe and fittings to avoid stress on the joints.

• Ensure installation is done in such a way that there are no chances of air entrapment.

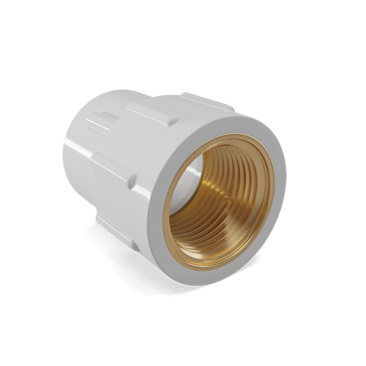

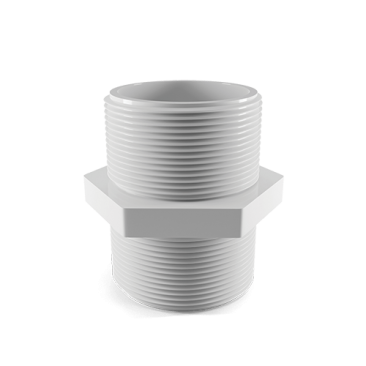

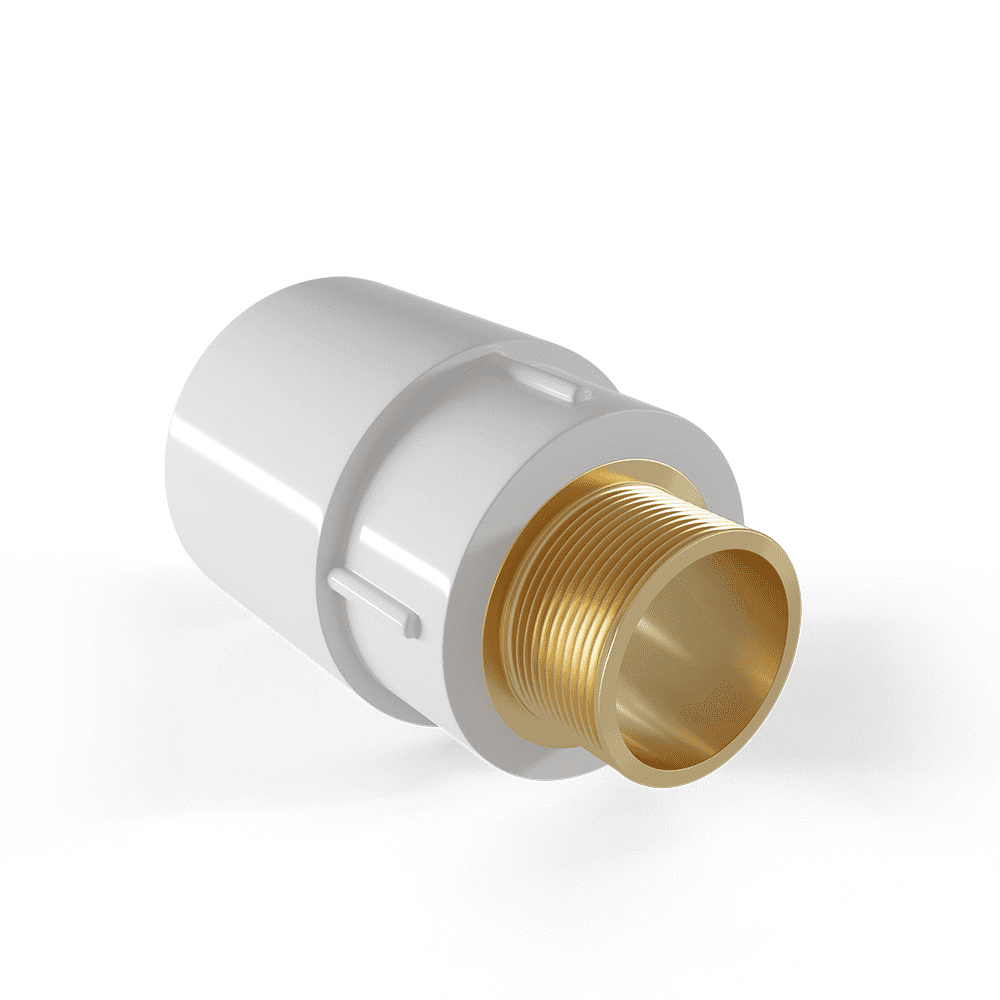

• Use only teflon tape as a thread sealant.

• Always conduct hydraulic pressure testing after installation to detect any leaks and faults.

• Wait for the appropriate cure time before pressure testing. Fill lines slowly and allow air to escape from the

system prior to pressure testing.

• Paint pipes exposed to sunlight with a water-based paint.

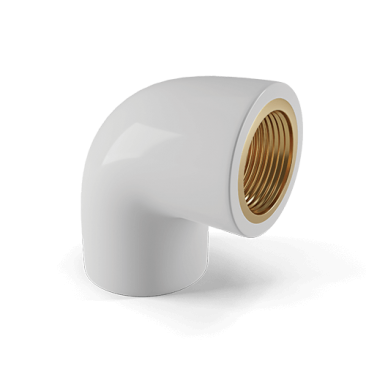

• Provide additional support to the brass side of ASTM/brass transition or other for keeping any heavy object to

support the weight of the metal system.

DON'TS

• Do not use metal hooks or nails to support/hold or put pressure on the pipes.

• Do not use straps and hangers with rough or sharp edges. Do not tighten the straps over the pipes.

• Never expose the pipe to open flame while trying to bend it.

• Do not drop pipes on edges from heights. Do not drop heavy objects on pipes or walk on pipes.

• Do not use air or gases for pressure testing.

• Do not use any other petroleum or solvent-based sealant, adhesive, lubricant or fire-stop material on ASTM

pipes & fittings.

• Do not use ASTM pipes and fittings for pneumatic applications.

• Do not use the ASTM piping system to support any metallic components.

• Do not use ASTM solvent cement that exceeds its shelf life, has become discoloured or has gelled.

CERTIFICATIONS & APPROVALS

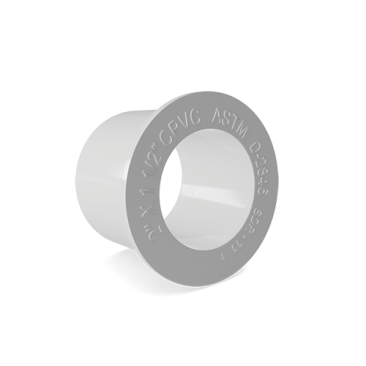

• ASTM Pipes and Fittings are manufactured as per ASTM D 1785 and ASTM D 2467.

• Heavy Pressure Plumbing Pipes are manufactured conforming to IS 4985 (Bureau of Indian Standards).

• Tested & approved by CIPET & SGS laboratory.

• Recommended by leading plumbing consultants pan India.

FAQs

-

Should specific type of primers and solvent cements be used for Finolex ASTM Plumbing pipes and fittings?

Finolex always recommends use of Finolex solvent cement which is specially manufactured to meet requirements of ASTM D 2564 Standards. All-purpose solvent cements are not recommended. Finolex recommends Medium Duty solvent cement for ASTM pipes upto 2”dia. and heavy duty solvent cement above 2” dia.pipes.

Primer, as per ASTM F 656, should be used for all ASTM pipes above 2”before applying the solvent cement. -

Can Finolex ASTM plumbing pipes and fittings be used for outdoor applications?

Finolex ASTM plumbing pipes and fittings contain stabilizers to protect pipes against harmful UV rays present in sunlight. Even after several years of usage, the performance of pipes is not affected. PVC pipe used in permanent outdoor exposures is recommended to be protected by light coloured water-based paint and not oil based paint.

-

Can Finolex ASTM Pipes be used for drinking / potable water?

Finolex ASTM Pipes can safely be used for plumbing applications including potable or drinking water. Finolex ASTM pipes are manufactured by using high grade Finolex PVC resin and unique compounding which is lead free. Thus, it is safe for potable water supply and more so,because of pvc material with smooth inner surface,there is no scaling or deposition. It is Corrosion-free and chemical resistant. It is tough & durable and immune to fungus, bacteria,algae formation.

-

Can Finolex ASTM pipes be used for transportation of compressed air and gases ?

Finolex or for that matter, any ASTM pipe, is not recommended for transportation of compressed air or gases. Not recommended for pneumatic applications.

-

What is the range of Finolex ASTM pipes ?

Finolex offers ASTM range from ½” to 8” dia pipes,in Schedule 40 and 80 series. For more information refer to the Finolex .

-

What is the difference between schedule 40 and schedule 80 ASTM Pipes ?

ASTM Schedule 80 pipes have more wall thickness and more pressure ratings than Schedule 40 ASTM pipes, for the given size.

-

How do I identify ASTM Schedule 40 and schedule 80 pipes ?

In ASTM PIPES ,Schedule 40 pipe has lesser wall thickness than schedule 80 pipe. The colour of the screen/matter printing on the pipe is BLUE.

Schedule 80 , has higher wall thickness than schedule 40. The colour of the screen/matter printing on the pipe is RED. This is for the ease of identification of pipes. -

What are the applications of Finolex ASTM Plumbing Pipes and Fittings?

Finolex ASTM plumbing pipes and fittings are designed for cold water plumbing applications in residential and commercial buildings, Vertical risers, ring/downtake lines. These pipes and fittings can also be used for swimming pools, hand pumps, salt water lines, water distribution mains, industrial process lines, sugar, paper and distillery lines