Sewerage pipes

Finolex underground drainage & sewerage pipes are intended to carry soil and waste from building to sewers or drains and then to treatment plants or disposal points. Finolex underground drainage and sewerage pipes are recommended for buildings where hygiene is a prerequisite such as hospital, hotels, school etc. They can also be used for rainwater collection and disposal. Finolex sewerage pipes are specially designed for underground - non pressure applications like gravity drainage, sewer flow and transportation of soil & waste discharge.

Finolex underground drainage and sewerage pipes are an ideal replacement of CI and DI piping systems because they are lightweight, corrosion free and long lasting. These pipes are 100% water tight, which makes them free from ingress and seepage of water, thus ensuring hygiene.

Finolex brings its trademark quality and precision stamp to its sewerage pipes to assure consumers of the best sanitary experience, by promising superior strength and durability. Our stringent quality assurance approach across all stages of manufacturing gives the product a high degree of reliability, which makes Finolex underground drainage and sewerage pipes a preferred choice of leading MEP consultants, architects, builders, plumbing contractors, plumbers and quality conscious people across the country.

These pipes are available in sizes 110, 160, 200, 250 and 315 mm in stiffness classes of SN-2, SN-4 & SN-8 and conform to IS 15328. Sewerage pipes come with selfit and ringfit sockets in a standard length of 3 & 6 meters. Selfit pipes are self-socketed and can be joined with the help of solvent cement; while Ringfit pipes need no threading or solvents for jointing and can withstand high pressures. Sewerage ringfit pipes are made with EPDM rubber rings that are long lasting and can withstand high pressures. For ease of jointing and to ensure better insertion, the use of Finolex rubber lubricant is recommended.

Applications

Technical Details

JOINTING

• For Selfit Pipes :

|

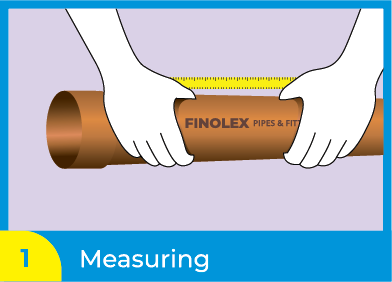

1. Measuring : Measure the required length of pipe and marking done. |

|

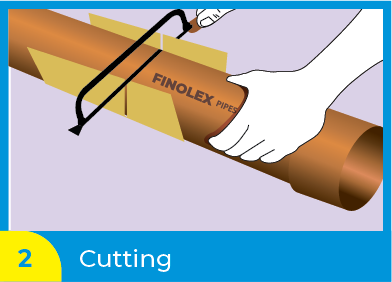

2. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

|

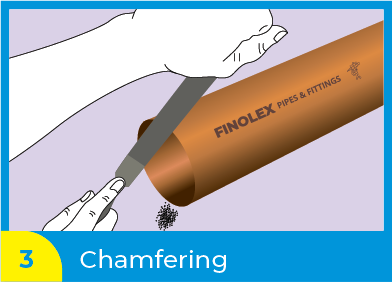

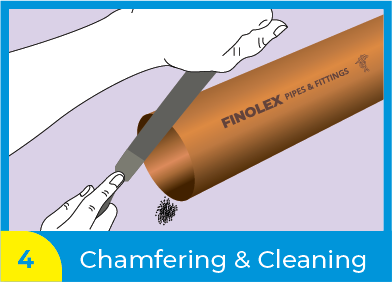

3. Deburring & Chamfering : All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe. |

|

4. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

|

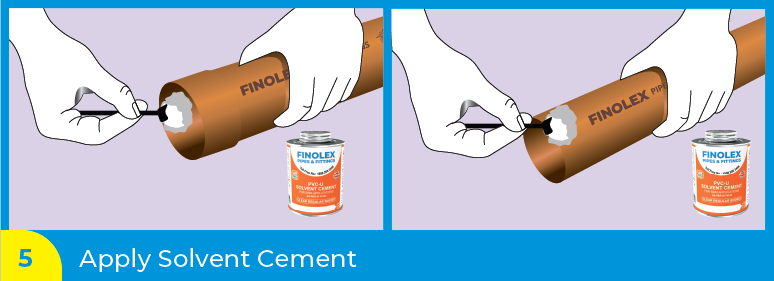

5. Solvent Cement Application : An even layer of cement should be applied to the outer side of the pipe and a medium layer of the plumbing solvent cement to the inside of a fitting. |

|

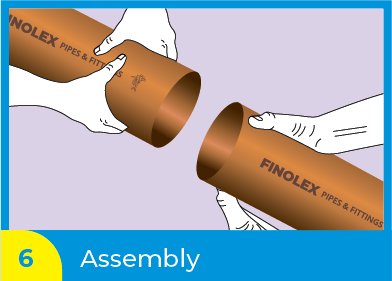

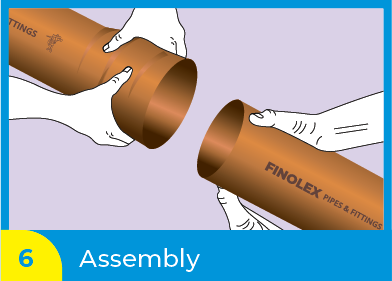

6. Assembly : Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting. |

• For Ringfit Pipes :

|

1. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

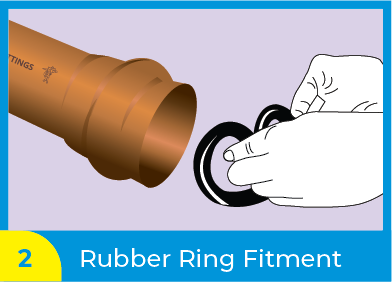

2. Rubber Ring fitment : Take rubber ring & clean for surface dirt of any & insert in pipe groove by hand. |

|

3. Cutting : he pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

|

4. Chamfering and cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. A 10° – 15° chamfer must be made at the end of the pipe. |

|

|

5. Lubricant application : Apply lubricant even layer on rubber ring prior to insertion. |

|

6. Assembly : Push the pipe in integrated ring socket end. |

FINOLEX SOLVENT CEMENTS & LUBRICANT

1) SOLVENT CEMENT

PVC-U Solvent Cement for SWR

Drainage & Sewerage Applications As per IS : 14182

| ml | 100 | 250 | 500 | 1000 |

| Container | Tin | Tin | Tin | Tin |

2) LUBRICANT

Rubber Lubricant used for installation of Ringfit pipes and fittings

| gms | 50 | 100 | 250 | 500 | 1000 |

| Container | Plastic Container | ||||

| Outside diameter of pipe (mm) |

Outside diameter of pipe (inches) |

Approx No. of Joints/Ltr. of Finolex Solvent Cement |

|||

| 110 | 4” | 50 | |||

| 160 | 6" | 28 | |||

| 200 | 8” | 15 | |||

| 250 | 10” | 9 | |||

| 315 | 12” | 5 |

Additional information

CERTIFICATIONS & APPROVALS

• Pipes are manufactured conforming to IS 15328 (Bureau of Indian Standards).

• Tested & approved by Central Institute of Plastics Engineering & Technology (CIPET).

FAQs

-

Which pipe do you recommend for sanitation waste out of a building and for connecting to chambers outside the building? What is it’s IS Standard ?

Finolex offers sewerage or underground drainage pipes that conform to IS 15328, for gravity drainage, sewer flow and transportation of soil and waste discharge.Finolex underground drainage and sewerage pipes are intended to carry soil and waste from building to sewers or drains and then to treatment plants or disposal points and septic tanks.

-

Are Finolex sewerage pipes suitable for pressurised application ?

Finolex sewerage pipes are specially designed for underground - non-pressure applications like gravity drainage, sewer flow and transportation of soil and waste discharge.

-

What are the various types of Finolex sewerage pipes ?

Sewerage pipes come with Selfit and Ringfit sockets in a standard length of 3 & 6 meters.Selfit pipes are self-socketed and can be joined with the help of solvent cement; while Ringfit pipes which come with EPDM rubber rings and can be joined by using lubricant.

-

What is the range of Finolex sewerage Pipes ?

Finolex sewerage Pipes are available in sizes 110, 160, 200, 250, and 315 mm in stiffness classes of SN-2, SN-4 & SN-8. 110,160,200 mm dia pipes are available in selfit socket type , whereas 250 and 315 mm dia pipes are available in ringfit socket type. .

-

What is the pressure rating of Finolex sewerage pipes ?

Finolex Sewerage Pipes are meant for Non-pressurised applications. However, it can withstand “external earth pressure “ and has STIFFNESS CLASS 2 KN/m² for SN2, STIFFNESS CLASS 4 KN/m² for SN4 and STIFFNESS CLASS 8 KN/m² for SN8.

-

Finolex sewerage pipes are equivalent to which SDR series ?

Equivalent SDR series of Finolex sewerage pipes are- SN 2 (SDR 51, STIFFNESS CLASS 2 KN/m² ) , SN 4 (SDR 41, STIFFNESS CLASS 4 KN/m²) and SN 8 (SDR 34, STIFFNESS CLASS 8 KN/m²) .

-

Which of the Finolex sewerage pipes has maximum stiffness and can withstand maximum external earth pressure ?

Finolex SN 8 (SDR 34, STIFFNESS CLASS 8 KN/m²) has the highest stiffness and can withstand more external earth pressure as compared to SN4 and SN2.

-

What is the SDR series ?

SDR ( Standard dimension Ratio) of sewerage pipe of any particular size is calculated by dividing OD ( Outside diameter ) of the pipe in mm by its WT (wall thickness) in mm.

-

Which are the most suitable applications for sewerage pipes ?

Finolex underground drainage and sewerage pipes are recommended for drainage and sewerage applications including buildings where hygiene is a prerequisite like hospitals, hotels, schools, and building complexes.